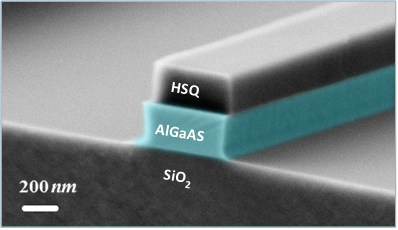

AlGaAs-on-insulator

The combination of nonlinear and integrated photonics enables Kerr frequency comb generation in stable chip-based microresonators. Such a comb system will revolutionize applications, including multi-wavelength lasers, metrology, and spectroscopy. Aluminum gallium arsenide (AlGaAs) exhibits very high material nonlinearity and low nonlinear loss. However, difficulties in device processing and low device effective nonlinearity made Kerr frequency comb generation elusive. We have demonstrated AlGaAs-on-insulator as a nonlinear platform at telecom wavelengths with an ultra-high device nonlinearity high-quality-factor (Q > 10^5). In these micro-resonators optical parametric oscillations are achieved with milliwatt-level pump threshold powers, which paves the way for on-chip pumped comb generation.

Amorphous Silicon

Amorphous Si (a-Si) is an interesting candidate as a core material. While the density of pure a-Si is 1.8% lower than that of c-Si, the refractive index of pure a-Si, at near-infrared wavelengths, is higher than that of c-Si. Amorphous silicon can thus be used as a waveguide core material on crystalline Si. As pure a-Si contains a large density of point defects and dangling bonds, the optical absorption at near-infrared wavelengths can be substantial. These point defects can be passivated to some extent by incorporation of hydrogen. In fact, hydrogenated a-Si made by deposition shows excellent electrical quality, and relatively low optical absorption. Amorphous silicon has already received a lot of interest both from a fundamental point of view and because of its possible use in solar cells and optoelectronic devices. Hydrogenated a-Si films can be deposited using a number of different techniques, including plasma enhanced chemical vapor deposition (CVD), RF sputtering and hot-filament CVD. The hydrogen content, void density, structural properties as well as optical and electronic properties have been studied intensively and depend critically on the exact processing conditions. In contrast, a-Si made by ion irradiation of crystalline silicon has reproducible properties that are insensitive to the preparation details, while voids seem to be absent in this material. Heat treatment of pure a-Si made by ion irradiation induces structural relaxation and reduces the defect density, which leads to an improvement in the optical and electronic properties. Overall, it seems that hydrogenated a-Si has better transparency in the near-infrared than pure a-Si. However, pure a-Si can be made more easily in a Si processing sequence, as it requires a single ion implantation step. Furthermore, pure a-Si has larger thermal stability then hydrogenated a-Si. Given these pro’s and con’s of pure a-Si, it seems interesting to study its applicability in microphotonic integrated circuits.